Browse the blogs

https://dermalife.co.in/ Open the blog

Welcome to Dermalife Skin and Hair Clinic – India’s Leading Center for Advanced Hair Restoration

Under the expert leadership of Dr. Gaurav Garg, a globally recognized specialist in hair transplant surgery, Dermalife is dedicated to delivering world-class solutions for hair loss. We understand that hair restoration is not just about aesthetics—it's about regaining confidence and enhancing quality of life.

At Dermalife, we combine the latest technology, cutting-edge techniques, and an artistic approach to achieve results that are natural, seamless, and virtually undetectable. Each treatment is personalized to match your unique needs, ensuring healthy, permanent hair growth and a transformation you can be proud of.

With a steadfast commitment to excellence, innovation, and patient satisfaction, Dermalife has earned its reputation as India’s most trusted name in hair restoration. Experience the difference—let us help you rediscover your confidence with results that truly speak for themselves.

Consult the Best Astrologer in Ahmedabad: Maa Ambe Astrologer Open the blog

If you are seeking insightful guidance or solutions to life’s challenges, Maa Ambe Astrologer in Ahmedabad stands out as a trusted name in the field of astrology. With a deep-rooted understanding of Vedic astrology, Maa Ambe Astrologer has earned a solid reputation for providing accurate predictions, effective remedies, and personal consultations that help individuals navigate various aspects of life.

Whether you're dealing with career uncertainty, relationship issues, health problems, or financial struggles, astrology can provide a deeper perspective and a roadmap to overcoming obstacles. Here’s why consulting Maa Ambe Astrologer can be an enlightening and transformative experience for you.

Who is Maa Ambe Astrologer?

Maa Ambe Astrologer is a renowned astrologer based in Ahmedabad, specializing in Vedic astrology, numerology, and horoscope readings. With years of experience and an in-depth understanding of astrological principles, they have helped thousands of clients find clarity and direction in their lives. Their ability to read and interpret the positions of celestial bodies and their influence on human life makes them one of the top astrologers in the city.

What sets Maa Ambe Astrologer apart is their compassionate and personalized approach. Unlike many other astrologers, they take the time to understand your specific situation and provide practical advice tailored to your unique circumstances. Whether you are seeking solutions for personal growth, professional success, or spiritual well-being, Maa Ambe Astrologer offers a holistic approach that combines astrological wisdom with practical life strategies.

Services Offered by Maa Ambe Astrologer

Maa Ambe Astrologer provides a wide range of astrological services designed to address various aspects of life:

Horoscope Reading: A detailed analysis of your birth chart, including the positions of planets and stars at the time of your birth, can reveal much about your personality, strengths, weaknesses, and life path. Maa Ambe Astrologer helps you understand your astrological profile and how it influences your decisions and experiences.

Career Guidance: Struggling to find the right career path or unsure about your job prospects? With the help of astrology, Maa Ambe Astrologer can offer guidance on the best career options based on your birth chart, along with remedies to overcome professional hurdles.

Marriage and Relationship Consultations: If you’re facing challenges in your personal life, whether it’s a relationship issue or marriage-related concerns, astrology can shed light on compatibility, timing, and potential issues. Maa Ambe Astrologer provides in-depth relationship compatibility analysis and practical solutions to strengthen relationships.

Health Predictions and Remedies: Astrology not only guides your mental and emotional state but can also help in predicting potential health issues based on planetary influences. Maa Ambe Astrologer uses this knowledge to offer remedies and suggestions to improve your well-being and prevent health problems.

Financial Astrology: Financial struggles can be tough to navigate. With the right astrological guidance, Maa Ambe Astrologer helps individuals make informed decisions regarding investments, business ventures, and other financial matters, ensuring prosperity and growth.

Spiritual Growth: For those seeking spiritual enlightenment, Maa Ambe Astrologer can help guide you on a path of self-discovery, meditation, and spiritual healing. The astrologer incorporates various methods to help you achieve inner peace and balance in life.

Remedies for Doshas: Certain Doshas (flaws or imperfections) in a birth chart can lead to obstacles or misfortune in various areas of life. Maa Ambe Astrologer provides remedies like gemstones, mantras, rituals, and other astrological remedies to nullify the effects of Doshas.

Palmistry: Along with astrology, Maa Ambe Astrologer also practices palmistry, the art of reading the lines and mounts of the hands to predict future events and uncover personality traits. Palmistry readings are often used as an additional tool to gain more insight into a person’s life.

Why Choose Maa Ambe Astrologer?

There are several reasons why Maa Ambe Astrologer is regarded as one of the best in Ahmedabad:

Experience and Expertise: With years of experience in Vedic astrology and a deep understanding of planetary movements, Maa Ambe Astrologer offers highly accurate readings and practical solutions. Their expertise ensures you receive reliable advice and guidance.

Personalized Solutions: Each person’s situation is unique, and Maa Ambe Astrologer takes the time to understand your specific challenges before offering remedies. Their personalized approach ensures that the solutions are tailored to your individual needs.

Confidentiality: Maa Ambe Astrologer maintains complete confidentiality, providing a safe and secure environment for clients to discuss their personal matters without fear of judgment. Your privacy is always respected.

Holistic Approach: The astrologer takes a holistic approach, considering various aspects of your life—career, relationships, health, and spirituality. This ensures that the solutions provided address the root cause of your challenges, not just the symptoms.

Effective Remedies: Maa Ambe Astrologer doesn’t just offer predictions but also practical remedies like gemstones, mantras, poojas (rituals), and astrological guidance to overcome obstacles and improve your quality of life.

Positive Reputation: The astrologer has garnered positive feedback from numerous clients who have experienced positive transformations in their lives after following the guidance and remedies provided. Word-of-mouth recommendations and testimonials reflect the trust and satisfaction of clients.

How to Consult Maa Ambe Astrologer?

Consulting Maa Ambe Astrologer is simple and can be done through various modes:

In-Person Consultation: Visit their office in Ahmedabad for a one-on-one session. This allows for a detailed discussion of your concerns, and the astrologer can provide face-to-face guidance and remedies.

Online Consultation: If you are unable to visit in person, online consultations via phone or video calls are available. This makes it convenient for individuals from all over India and abroad to benefit from Maa Ambe Astrologer's expertise.

Telephonic Consultation: For those who prefer a quicker consultation, phone readings are also available. Simply schedule a call, and you’ll receive expert advice without leaving the comfort of your home.

Conclusion

If you're at a crossroads in life or simply seeking guidance on important decisions, Maa Ambe Astrologer in Ahmedabad offers the perfect blend of astrological wisdom and compassionate counseling to help you move forward with confidence. With their accurate predictions, personalized solutions, and proven track record, you can rest assured that you're in safe hands.

Contact Maa Ambe Astrologer today to schedule a consultation and take the first step toward unlocking the answers you seek and achieving a more fulfilling life.

Web: https://www.maaambeastrologer.com/

Latest Blog Posts

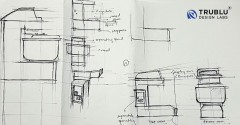

Product Design Open the blog

Trublu Design Labs unlocks innovation with visionary Product Design and Development, transformative reverse engineering, and captivating .packaging designs

Latest Blog Posts

Product Design Agency in Mumbai: Innovation Starts at Trublu Design Labs

Product Design Agency in Mumbai: Innovation Starts at Trublu Design Labs

Advanced Laparoscopic Surgery Open the blog

Advanced laparoscopic surgery refers to more complex surgical procedures that involve higher levels of skill and precision, intricate technique and highly specialized tools. While laparoscopic surgery is in itself a challenging procedure to complete, advanced laparoscopic surgery is considered more difficult to perform because it is usually conducted on more challenging anatomical areas and involves higher risk. Robotic assistance and 3D laparoscopy may be used in advanced laparoscopic procedures to enable higher precision in complex procedures like pancreatic surgery, appendectomy, colorectal and gynecological surgeries, vagotomy, cardiomyotomy, or intricate pelvic reconstruction surgery.

Latest Blog Posts

factory for sale in noida Open the blog

Noida has become one of the hottest destinations for setting up manufacturing and industrial operations. At Prithvee.com, we specialize in connecting you with the most lucrative industrial properties and factories for sale in Noida.

Latest Blog Posts